LLDPE (Linear Low Density Polyethylene), LDPE (Low Density Polyethylene) and HDPE (High Density Polyethylene) are all polyolefins with unique molecular structures that set them apart. Liner polymers are used to create a wide variety of goods including telecom ducts, fuel tanks, meter and valve boxes and so much more.

Polyethylene is a polyolefin, which are high molecular weight hydrocarbons that include high-density polyethylene, low-density polyethylene, polypropylene copolymer, polymethyl pentene and polypropylene. These represent the only plastics with a lower specific gravity than water, or in other words, they are the only plastics that weigh less than water. While some forms of these materials are sensitive to oxidization and UV light, LLDPE is resistant to both of these things as well as other natural environmental strains.

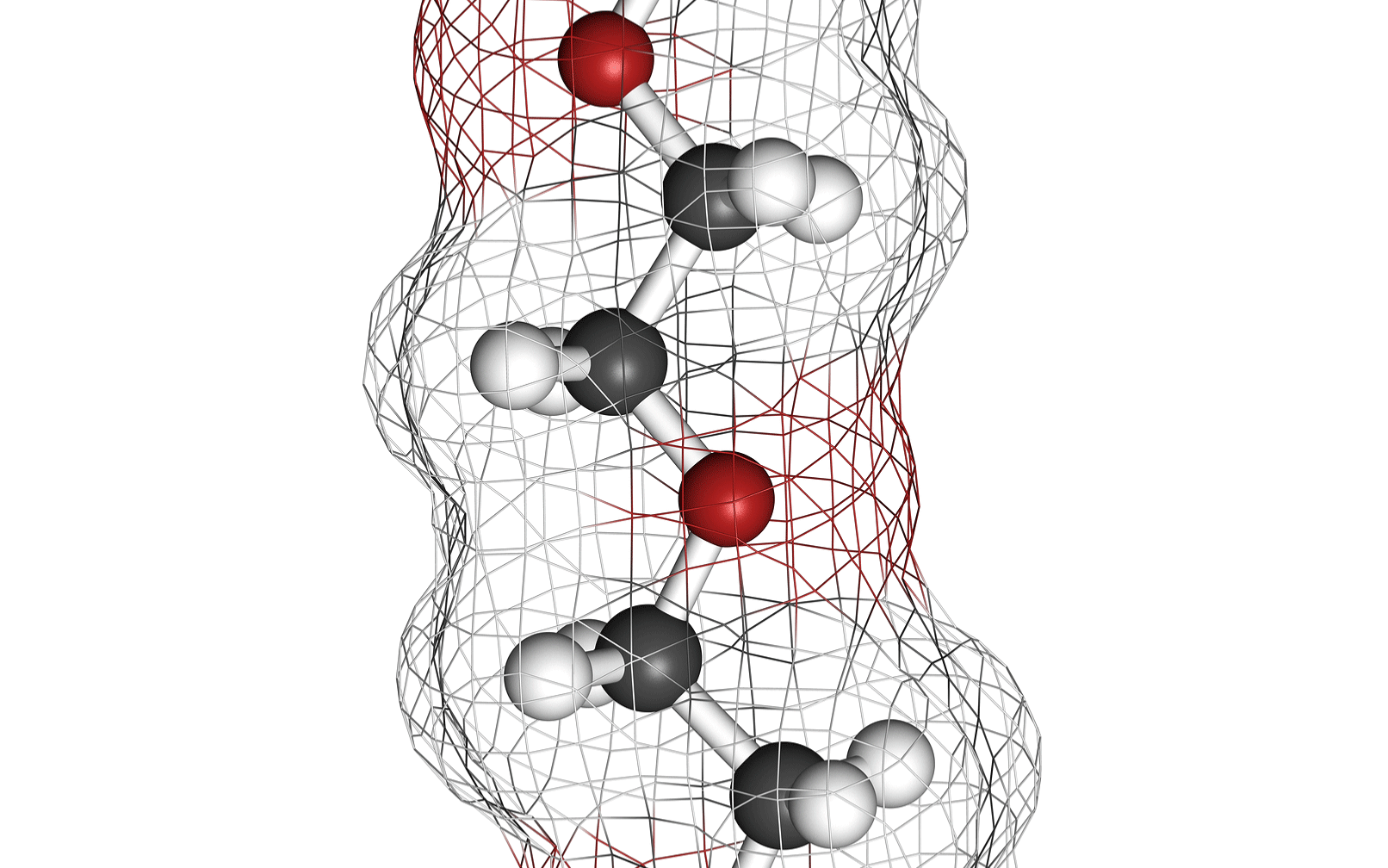

Ethylene is polymerized in order to create a fairly straight polymer chain. These chains branch out in unique ways from the main chain depending upon the varying degree of branching in their molecular structure.

LDPE (Low Density Polyethylene): LDPE has the most extensive branching compared to other polyolefins. As a result, it is low density and has a less compact molecular structure. It has a density of 0.910-0.925 g/cm3.

LLDPE (Linear Low Density Polyethylene): LLDPE is known for its vast number of short branches. While its branches are shorter, there are more of them and they are able to move against one another upon elongation without entangling together. On the other hand, LDPE’s longer branches easily tangle up with one another. That’s why LLDPE is much stronger and able to withstand greater impact and puncture damage. It has a density of 0.91-0.94 g/cm3.

We prefer to use LLDPE due to its extreme strength and durability. Our resin made from LLDPE allows us to create the strongest trashcans, lighting products, and planters on the market.

HDPE (High Density Polyethylene): HDPE’s polymer chains include less branching. As a result, it is a denser material that is more ridged and less permeable than LDPE. HDPE is a clean product to produce as it creates no harmful emissions and leaks no toxic chemicals into soil or water. HDPE is among the most commonly used plastic in the US. It has a density of 0.941-0.965 g/cm3.

Benefits Of LLDPE Compared To HDPE & LDPE

LLDPE and LDPE account for 35% of Western Europe’s total polyolefins production, totaling 22.1 million tons per year. Yet, LLDPE is slightly thinner than LDPE. This grants LLDPE added flexibility and greater stretch consistency. This is how our products are able to withstand heavy impact damage. When hit with a great amount of force, LLDPE can flex and bend into the impact and then snap back into place. Opposed to shattering into millions of tiny pieces, as more dense and brittle forms of polyolefins are prone to.

HDPE is one of the most commonly used plastics in the US. It is labeled as plastic #2 for recycling purposes, and is often used for plastic bags, milk jugs and refillable bottles. HDPE is used to craft buckets, planters and other garden products, although it is not as durable as LLDPE. It is more commonly used in packaging and manufacturing because of its strength and ability to provide a solid barrier against water, insects, rot and chemicals.

While other polyolefins are loaded with countless strengths and benefits, LLDPE is the greatest material for planters, and lighting products. Some of the unique benefits that make this true include:

-Flexibility and elongation allows for high impact resistance. Trust us, we have tossed our planters from rooftops and even seen them hit by cars. They can survive so much more than your average planter thanks to the unique flexibility of LLDPE.

-LLDPE is resistant to UV rays, plus we add additional UV-12 inhibitors in order to extend the life cycle of our product’s vibrant colors. It takes much longer for our planters and lighting products to show the same fading and discoloration from the sun as traditional materials.

-Puncture resistant, this goes in line with the material’s overall flexibility.

-Long lasting due to high durability. LLDPE remains a great looking product for many years, hence why we are able to offer one of the best warranties in the industry.

-LLDPE has increased frictional resistance.

-LLDPE has unique properties that make it ideal for applications in which high mechanical properties are necessary.

-LLDPE has solid mechanical properties that contribute to lower maintenance than comparable materials.

Is LLDPE Recyclable?

Yes! Since LLDPE maintains its base properties during the recycling process, it is a commonly recycled material. It can be recycled again and again, eliminating waste while serving countless functions. Recycling code 4 typically identifies LLDPE.

We offer a 100% post-consumer recycled black material that can help maximize the LEED MRc4 credit. All of our products can be recycled when they are no longer of use.

Which Is Better?

It’s impossible to compare plums and peaches; while both are yummy fruits they are too unique to say which is better outside the lines of personal preference. Different polymers are similar in that they serve different functions best. Comparisons cannot be made based upon the level of the polymer material alone. Instead, it’s largely dependent on what the material is being used for.

When it comes to planters and lighting products, LLDPE makes a durable, long lasting and good-looking material. That doesn’t mean HDPE and LDPE don’t serve other areas equally well. Yet, since LLDPE is more flexible and less brittle it is much more resistant to common damages experienced by planters and lighting products that are kept outside.

We welcome you to experience the difference of our specially manufactured resin made from LLDPE. Shop our full collection of hardy planters, lighting products and more.