Custom Prototyping

Large Format 3D Printing Capabilities

Modern advancements in technology have allowed us to utilize CAD files in an effort to work more efficiently in making alterations to 5G or street lighting poles. We understand that, in some cases, many clients require better visualization and evaluation of the final product design before moving forward.

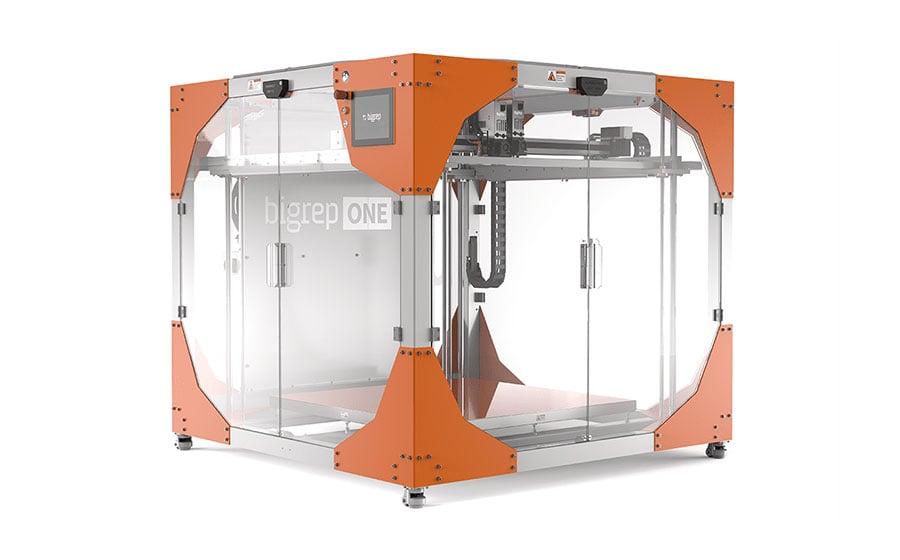

3D printing has revolutionized the way we develop and manufacture products. With the help of our large-scale 3D printer, TerraCast can now create prototypes for our clients quickly and cost-effectively, enabling faster iterations and improvements on our clients' designs before committing to design approval, and ultimately, investment in tooling for mass production of resin parts.

TerraCast owns one of the largest 3D printers available on the market, with a build volume of a one-cubic meter. Our printer allows us to print a large part in a single print rather than many small components, reducing the need for assembly. 3D printing your prototypes with TerraCast helps to streamline the product development and testing procedures to establish form, fit and function. Smaller capital investment costs coupled with faster turnaround make our 3D printing service ideal for clients with one-off projects or designs.

Faster Iteration

Testing a prototype before creating a mold allows for faster iteration of designs. It enables designers and engineers to identify and address issues early in the process, making it easier and less expensive to make changes.

Reduced Costs

Creating a mold for manufacturing can be expensive, particularly for complex designs. Testing prototypes before committing to creating a mold can help to reduce costs by allowing designers to identify and address issues early in the design process.

Greater Design Flexibility

Testing prototypes enables greater design flexibility. With prototypes, designers and engineers can explore various design concepts and test different configurations without being limited by the constraints of a mold.

Improved Product Testing

Prototypes can be tested in real-world scenarios, allowing for more accurate and comprehensive testing. Having a physical piece can facilitate approval for proceeding with the project.

Better Collaboration

Testing prototypes enables better collaboration between designers, engineers, and other stakeholders in the product development procedure. It allows stakeholders to see and test prototypes, providing valuable feedback that can inform the design process.